Registration is Closed.

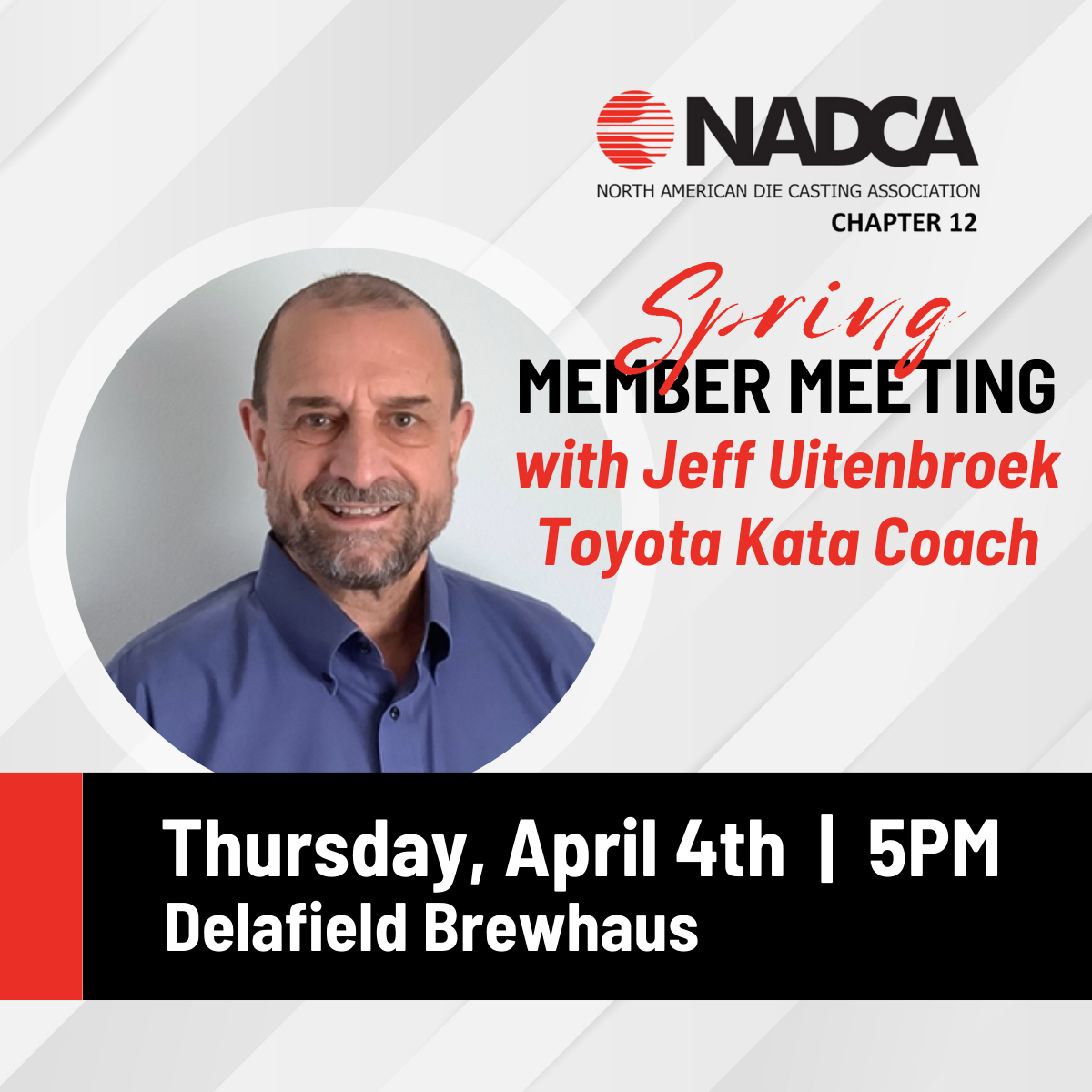

Join us Thursday, April 4th for networking, dinner, and a presentation by Jeff Uitenbroek a Toyota Kata Coach.

Thank you to our Spring Member Meeting Sponsor

Lean and Continuous Improvement Using Toyota Kata

Many organizations have invested time and money in Continuous Improvement intending to be “Lean like Toyota”, only to be dissatisfied with the return on that investment. Lean and Continuous Improvement tools are widely available and understood.

Other organizations have had limited success copying Toyota....Why? What is missing?

We saw all the tools Toyota used on their shop floor. We did not recognize the patterns of Leadership, Mentoring, and Way of Thinking, that created the tools. These patterns are the core of Toyota Kata.

The word Kata, literally translated as “Way of Doing”, are routines, or patterns of activity, that when practiced provide a methodology to master a skill.

Toyota Kata describes 3 basic concepts needed to master improvement.

Ø Improvement Pattern: → Identifies and drives improvement of our processes

Ø Target Process Conditions: → Describe how we want a process to work

Ø Mentoring Pattern: → Guides and teaches the Improvement Pattern

Agenda:

5:00 to 6:00 PM - Networking

6:00 to 6:30 PM - Dinner

6:30 to 7:30 PM - Presentation

7:30 to 8:00 PM - Q & A

On the Menu:

Brewmaster Buffet including Garlic & Thyme Rubbed Roast Pork Loin, Chicken Alfredo, Garden Salad, Sour Cream and Chive Mashed potatoes, and Green Beans Almandine.

Registration Deadline:

End of Day, Tuesday, April 2nd

About the Speaker

Jeff Uitenbroek

Toyota Kata Coach

Jeff is experienced in the Toyota Kata methodology and integrating Toyota Kata into the continuous improvement culture of a business.

He gained this expertise as a member of the Modine Manufacturing Company leadership team. At Modine, working closely with Mike Rother the author of ‘Toyota Kata’, the continuous improvement culture was transformed to create and nurture improvement capability throughout the organization using Toyota Kata methodology. Modine and Jeff are acknowledged in Mike’s book.

Jeff is a member of ASQ and received ASQ Six Sigma Quality Black Belt Certification. With 3M Company he led a business expansion into Europe on an expat assignment in Netherlands, and held operations, engineering, quality, and EHS leadership roles in the optical storage media industry.

Thank You to Our Annual Sponsors